Precision CNC Machining & Drilling

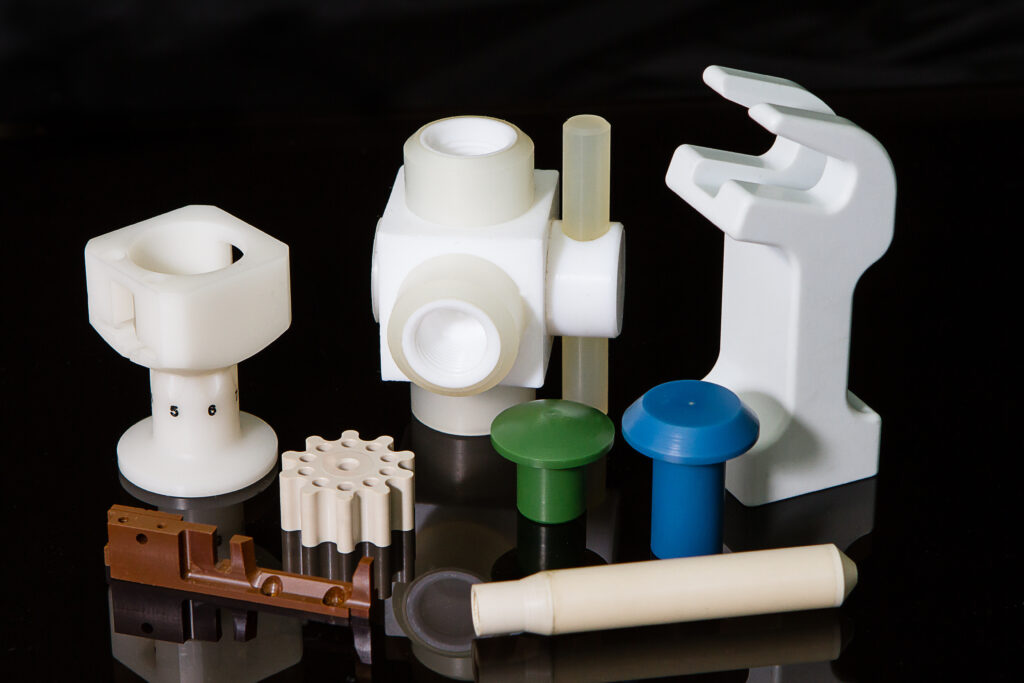

Few companies have earned the stellar reputation that R. Blaine Industries (RBI) has for the consistent ability to machine the most complex parts while maintaining an extremely high level of quality. CNC turning and milling are specialties on which we pride ourselves, including capabilities for gear cutting / hobbing, broaching, spline cutting, facing, contour turning, form turning, taper turning, and straight turning.

We are expert in the very specialized field of plastics machining and drilling. We routinely work with VTEC, PEEK, FRP, nylon, acetal, polyurethane, PTFE, filled PTFE, and Vespel, just to name a few.

We also offer mechanical micro drilling of holes from 0.0015″ in diameter and up, to depths of 10x diameter. Our holes are burr free and can be countersunk on the back side as required.

However, the spectrum of our ability is only enhanced by the extensive range of materials with which we are comfortable working: machinable ceramic, graphite, alloy steels, aluminum, aluminum-bronze, cold rolled steel, tool steel, carpenter 20, molybdenum, and titanium.

Our ANSI-endorsed manufacturing ability allows us to make anything from prototypes to hundreds of thousands of units with lead-times tailored to the needs of our valued customers.

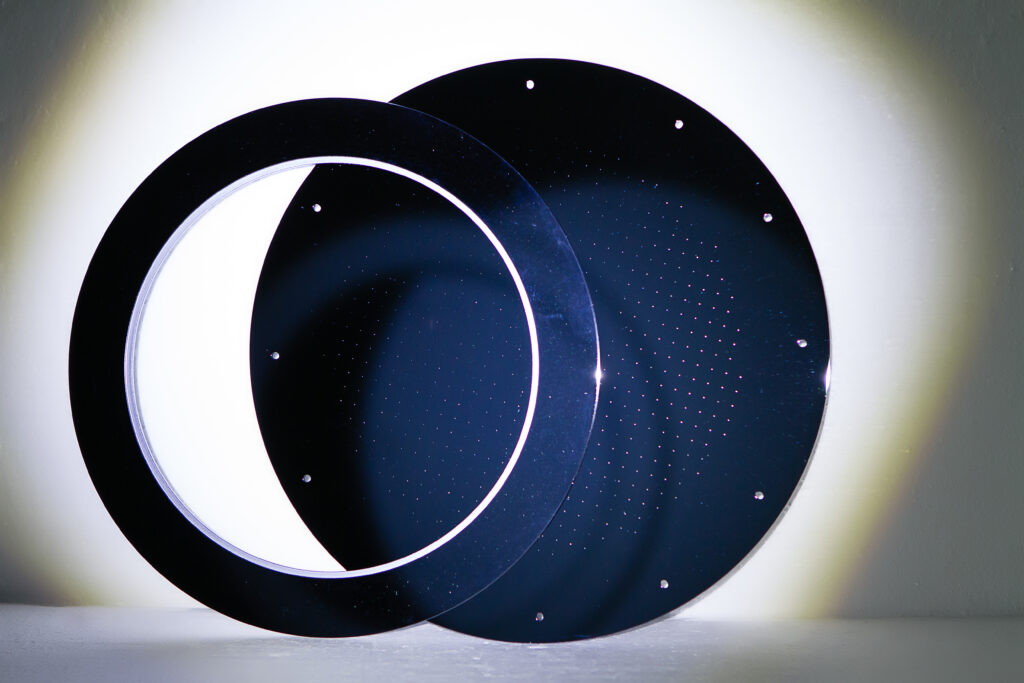

Semiconductor Spare Parts & Part Refurbishing Services

Spare and Consumable Parts for Semiconductor Manufacturing

R. Blaine Industries (RBI) is the leading independent manufacturer of precision engineered spare and consumable parts for semiconductor processing equipment. We provide a quality alternative to parts from OEMs such as Applied Materials, Tokyo Electron, Lam Research, Varian, and many others.

We support components for etch, CVD, PVD, back-end test and related operations. Our parts feature engineering design enhancements which improve equipment performance and reliability. We manufacture parts from many materials including plastics, aluminum, quartz, ceramic, silicon, graphite, etc. RBI parts are typically far less in cost compared to OEM parts, usually with shorter delivery times.

Refurbishing of Semiconductor Manufacturing Parts

RBI also offers repair and refurbishing services to extend the useful life of semiconductor processing parts and assemblies. The savings possible by refurbishing can be quite significant, normally a fraction of the cost of new OEM parts. This reduces overall consumable costs.

Our experience and engineering skills with semiconductor parts even comes into play with repairs: we can modify many parts to improve flawed original designs. And often our repaired parts last longer than OEM originals. Typical items that can be refurbished include…

- Electrostatic chucks (ESCs)

- Process Chambers

- Slit Valves

- Showerheads

- Upper Chamber Assembly, DPS Metal

- Quartz Wafer Boats

- Aluminum Electrodes

- Any Thermal Spray Ceramic Part

Gear Cutting & Ultra-Hard Materials Grinding

Plastic & Metal Gear Cutting

R. Blaine Industries (RBI) manufactures precision plastic and metal industrial gears to your exact specifications. Our shop is equipped with hobbers and shapers designed to cut gears with precise accuracy. Our spur and helical gear cutting equipment has a capacity of up to 36″ pitch diameter and 2 diametrical pitch. We can also manufacture fine pitch gears with pitch diameters from .250″ and a diametrical pitch range of up to 120.

We routinely hold a tooth-to-tooth composite error of 0.0005″ with a total composite error of not over 0.001″. Our state of the art gear cutting equipment, together with advanced hob grinders and checking equipment, assures that the most critical quality spur and helical gear requirements will be fully met.

We specialize in the manufacture of Pump Gears, and manufacture gears for many industries in a wide range of materials including:

- PTFE

- PEEK

- Nylon

- Acetal

- Brass

- Stainless Steel

- Hastelloy

- Carpenter 20

From engineering to inspection, RBI manufactures the finest gears available to industry.

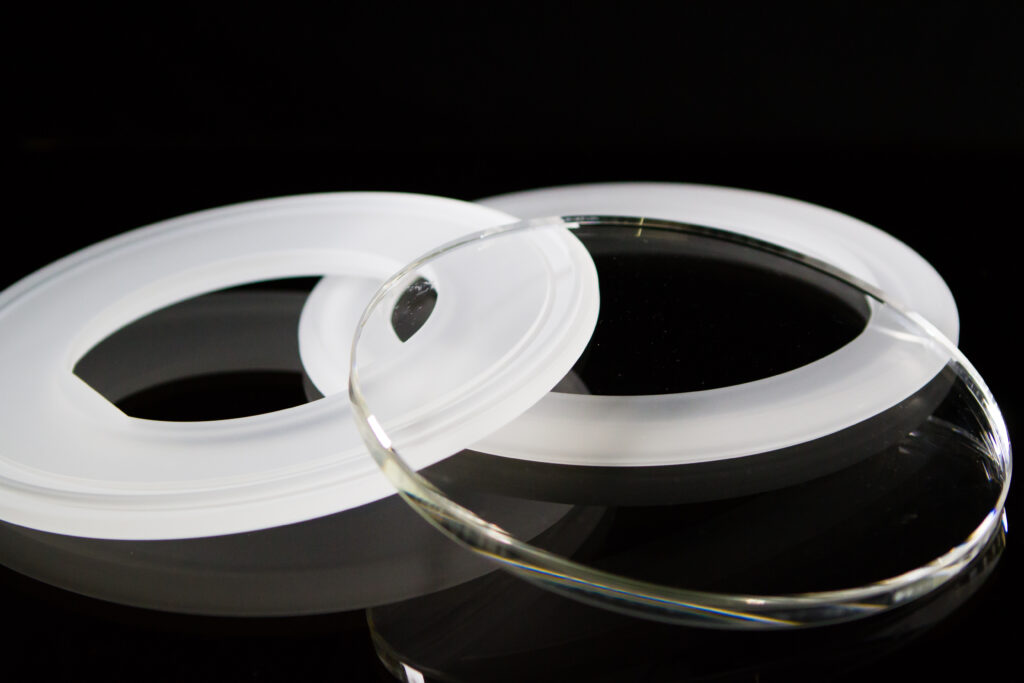

Ultra-Hard Materials Grinding

R. Blaine Industries (RBI) offers precision machining and grinding of quartz, technical ceramics, silicon and other hard materials. We have a long history of meeting extremely close tolerances with exacting precision and superb quality through state of the art equipment and technological innovation.

Customers who come to us typically have a critical application that requires extremely precise tolerances in ultra-hard materials. We serve the demanding needs of the semiconductor, military, aerospace, medical, and chemical/wear application industries.

Plastic Injection & Compression Molding

R. Blaine Industries (RBI) custom molds most plastics, PTFE, PEEK, FRP (Fiberglass Reinforced Plastic), both standard and customer specific, using automatic and semi-automatic injection and compression processes. Our innovative, non-traditional processing methods enable us to meet the most challenging requirements for high-quality, economical parts. In addition to the many virgin resin compounds we offer, special blends are routinely formulated in our modern laboratory to meet unique requirements.

Injection Molded Prototypes & Short Run Production

We offer rapid turn mold making and injection molding with cost saving aluminum tools. Our production scheduling is designed to accommodate last-minute orders for parts small or large. Typical lead times are in the three to four week range, often less. We process both commodity and engineering grade resins. When you need the exact part, and a 3D printed part will not suffice for advance product testing, we stand ready to supply those prototypes or limited production parts fast.

Metal Bonding & Insert Molding

RBI is a recognized leader in bonding PTFE to a variety of metals. This unique capability ranges from surface bonding to total encapsulation where the hot plastic (including PTFE) shrinks around the metal insert creating a tight physical bond. We combine precision molding expertise and innovative metal bonding techniques with a nearly limitless selection of PTFE compounds. With capacities to 1,000 tons, our modern presses are designed for compression and compression transfer applications.

PTFE Design Engineering

Our engineers and designers are experienced in all phases of PTFE molding. They are an integral part of the entire process from conception through production. Using our CAD system, we can help design parts and tooling, then cost effectively fabricate them using our CAM programming and CNC machining.

Coatings, Metal Bonding & Finishes

R. Blaine Industries (RBI) offers custom coatings. This division was originally established to fill a void in the market for specialty coatings requiring a high degree of technical expertise, engineering and application skills. We specialize in the application of fluoropolymer coatings such as PTFE, FEP, PFA, PPS, PVDF, ETFE and ECTFE in both liquid and powder forms. Non-fluoropolymer materials such as VTEC polyimide, silicone, Viton, urethane, epoxy, and enamel are also part of our capability.

These materials are applied utilizing a wide variety of application techniques including conventional spray, electrostatic spray, and fluidized bed, as well as dip and spin. The coatings used at RBI have been developed and engineered to solve problems associated with chemical resistance, wear resistance, abrasion resistance, lubricity, electrical conductivity, thermo insulation, and lack of release.

RBI is a recognized leader in bonding PTFE to a variety of metals. This unique capability ranges from surface bonding to total encapsulation where the hot plastic (including PTFE) shrinks around the metal insert creating a tight physical bond. We combine precision molding expertise and innovative metal bonding techniques with a nearly limitless selection of PTFE compounds. With capacities to 1,000 tons, our modern presses are designed for compression and compression transfer applications.

RBI’s coating division employs the latest process equipment including climate control, computer controlled automatic coaters, computer controlled ovens, and statistical process control software. All products undergo a rigorous inspection process using modern measurement and test equipment before packaging and shipping.

Additional finishing services include thermal spray, aluminum anodizing and hard coat.